In the journey from startup to thriving business, there’s often an unsung hero: effective inventory management. For small businesses, finding the right solution to track and manage stock can be a powerful catalyst for growth and expansion.

As you scale up your business, embracing effective inventory management solutions is not just an option – it’s a necessity. This article explores some of the best inventory management practices for small- to medium-sized businesses (SMEs), highlighting some of the strategies that have proved successful in 2024.

Then, we’ll zero in on how the right inventory management software can take your business to new levels of success.

What is inventory management?

Inventory management is the process of acquiring, storing, and managing all the products that form part of your inventory, from raw materials to finished goods. These may include:

- Raw goods – Materials or substances used in early production, such as wood, plastic, or metal

- Work in progress – Partially finished products that will eventually become products for sale

- Finished goods – Products that are ready and available for customers to purchase

- Operational goods – Any materials or supplies that are used in production but are not part of the final product, including tech equipment, office supplies, and clearing supplies

By systematically managing your inventory, you can work towards improving efficiency in many areas of your business. Your overarching goal should always be to minimize costs while maintaining optimal stock levels.

Check out our video on Best Practices for Inventory Management for a roundup of the most practical strategies to achieve growth and increase your profits.

A scaling path for small businesses

There are 33.2 million small businesses in the US, accounting for 99.9% of all American businesses. To break your way out of that category, you’ll need a plan to scale – and you’ll encounter a few critical inventory management decision points along the way.

If you’re an etailer, look no further for inspiration than Warby Parker. Launched in 2010 as an ecommerce website by four friends, the brand has emerged as an online-only eyewear retailer specializing in affordable and stylish glasses.

The company credits its success to its direct-to-consumer model, which has proven a more flexible, cost-effective alternative to using an eyeglass store as a middleman.

In Warby Parker’s startup years, founders would pack and ship glasses from their apartments. However, their commitment to quality, affordability, and excellent customer service won over customers in no time

Warby Parker was able to expand its product line up, launch brick-and-mortar retail stores, and achieve a valuation exceeding one billion dollars.

Starting small, riding the ecommerce wave, then scaling fast is the dream for many small business owners. But how do companies like Warby Parker achieve such rapid growth?

Choosing an inventory management model

One of the most important decisions small businesses make is to choose between establishing their own facilities versus using third-party logistics (3PL). This choice represents a significant strategic pivot that can shape the future trajectory of a brand.

Third-party logistics for inventory management

Managing inventory via third-party logistics (3PL) offers certain advantages for small-scale ecommerce and retail businesses.

- Cost efficiency – Inventory management costs such as storage are among the most significant expenses for ecommerce retailers. By outsourcing logistics to a third-party provider, businesses can often benefit from economies of scale. 3PL providers typically manage multiple clients and can spread fixed costs across their customer base, resulting in cost savings for each individual retailer.

- Focus on core competencies – Small businesses often have limited resources, and managing inventory and logistics can be time-consuming. Outsourcing these tasks to a 3PL provider allows retailers to focus on activities that directly contribute to the growth and success of their business.

- Scalability and flexibility – Small retailers may experience fluctuations in demand, especially during peak seasons or promotional periods. 3PL providers offer scalability and flexibility, allowing businesses to adapt quickly to changes in inventory requirements.

Of course, an often-cited con of 3PL is lack of control. You’re effectively relying on a third party to handle a major aspect of your business, and any disruptions, mismanagement, or communications failures on their end can directly affect your operations.

Depending on the 3PL partner you choose to work with, you may also struggle with limited visibility over the day-to-day handling of your inventory. Without full oversight and accessibility, you might encounter challenges in maintaining quality standards, timely order fulfillment, and accurate inventory tracking.

If you’re in a specialized industry like cannabis, it’s well worth bearing this in mind – and finding a 3PL provider that understands your products’ unique needs and regulatory constraints.

In-house inventory management systems

By contrast, managing your inventory in-house provides more control over activities but requires an investment in scaling your human resources and facilities.

Here are a few reasons why small businesses may prefer to use in-house operations:

- Control – In-house operations allow small businesses to have greater control over their inventory management and logistics processes. They can customize their operations to meet specific needs and maintain control over quality, shipping times, and customer experience.

- Brand image – Having control over operations can help businesses maintain and enhance their brand image. They can ensure that products are handled and shipped in a way that aligns with their brand values.

- Flexibility – As market and customer demands shift, businesses can quickly make adjustments, implement new strategies, or introduce innovative packaging and shipping methods without relying on a third party.

- Cost savings – In-house operations can often be more cost-effective for small businesses, especially as they scale. By managing their logistics internally, brands can avoid 3PL fees and potentially reduce overall operational costs.

- Data and insights – Businesses can directly access valuable data and insights into customer behavior, inventory management, and operational efficiency. Armed with this information, they can make informed decisions and continuously improve their processes.

For many small businesses, in-house inventory management systems are a long-term strategic investment. While setting them up may require effort and resources, they believe that building and controlling their logistics capabilities will pay off in the long run.

Managing multi-location retail and storage

Multi-location inventory management means that instead of having a central warehouse holding all your inventory, you spread it out amongst multiple storage locations. Most likely, you also sell through several different channels.

In large markets like the US, multi-location inventory allows SMEs to offer competitive delivery options — either a next-day or same-day delivery, both of which are critical standards in the fast-paced ecommerce world today.

For example, fashion retailer Zara benefits from multi-location warehouses to quickly respond to changing fashion trends. Having warehouses all over the world enables a fast fashion model, ensuring that new clothing lines reach stores and online customers promptly.

In the cannabis sector, MedMen is a chain of cannabis dispensaries in multiple U.S. states with 65 locations. They use multi-location warehouses to manage their inventory efficiently.

This helps them maintain a consistent supply of cannabis products in their stores and meet customer demand. It lowers their shipping costs and delivery timeframes while making a positive impression on customers.

Retailers like Zara and MedMen benefit from multi-location retail and storage strategies in several ways:

- Reduced shipping times – Having multiple retail and storage locations allows ecommerce brands to position their products closer to customers. This significantly reduces shipping times, leading to faster deliveries and improved customer satisfaction.

- Cost savings – By strategically distributing inventory across multiple locations, retailers can minimize shipping costs. They can choose the most cost-effective shipping routes and reduce the need for expensive expedited shipping options.

- Inventory management – Multi-location storage enables more efficient inventory management. Brands can keep track of inventory levels in real time and reduce the risk of stockouts or overstock situations. This leads to better overall inventory management efficiency and cost control.

- Seasonal demand – Brands with seasonal products can benefit from multi-location storage. They can allocate inventory to locations where demand is highest during specific seasons, ensuring products are readily available when needed.

The role of inventory management software for small businesses

Inventory management software is a significant asset for small businesses and SMEs. More than just a helpful tool, it plays a critical role in the success of small-scale enterprises.

In a sector where every resource matters, this software enhances product management efficiency and accuracy, which is vital for staying agile and thriving in competitive markets.

One of the most basic functions of inventory management software is to provide a clear overview of stock levels. This kind of information is the very minimum business owners need in order to effectively replenish stock and avoid issues like overstocking or understocking.

On top of this basic data, inventory management solutions should offer analytical tools. These features provide insight into inventory turnover, helping to identify which products are popular and which aren’t. With easy access to this critical insight, you can plan purchasing and marketing strategies with much more confidence.

Software equipped with demand forecasting can analyze past sales and market trends to predict future sales. This helps small businesses in strategic planning and staying ahead of market shifts.

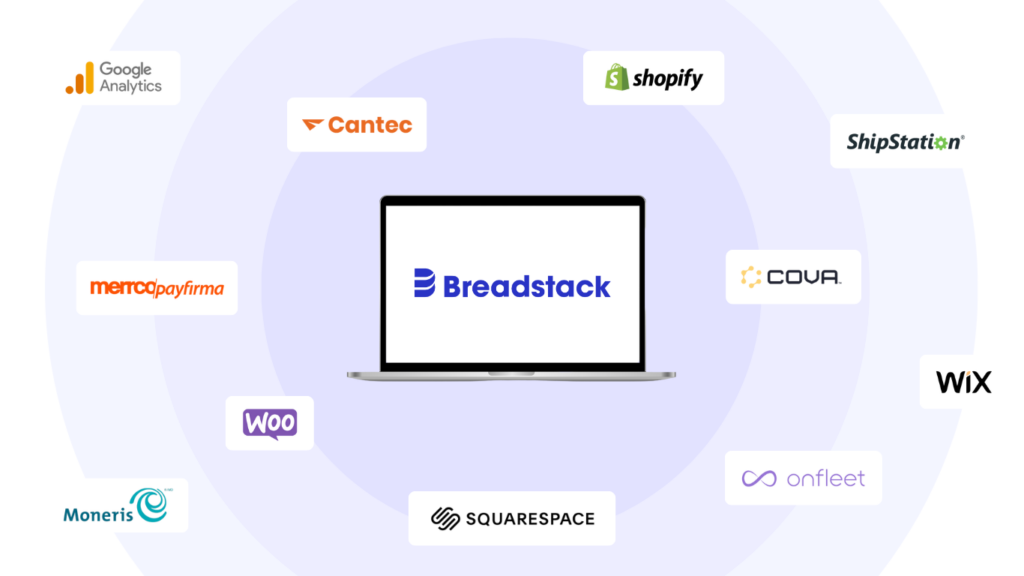

Integrating your tech stack

Spreadsheets are fine when you’re just getting started. But scaling your business requires transitioning from primitive, manual tools to cohesive tech stacks that simplify and speed up your operations.

Solutions like Breadstack integrate with popular ecommerce platforms (think: Shopify and WooCommerce) to unify your sales channels and warehouses, and give you oversight on the flow of inventory between them.

Meanwhile, integrating your inventory management and point-of-sale (PoS) system ensures that you always have access to real-time, on-the-ground data on the status and health of your inventory. This is an important aspect of perpetual inventory management.

Breadstack incorporates all these elements to provide real-time updates on your inventory, advanced analytics to help you make the right decisions at the most opportune moments, and modernize the way you manage your inventory and customer relationships.

Get started with your inventory management solution

As your business looks to make its mark in 2024, don’t underestimate what the right inventory management system can offer to help you get there. These solutions represent a blend of tech innovation, strategic foresight, and operational excellence, laying the groundwork for your future growth and success.

If you’re a small business looking to manage products or track physical inventory across multiple channels and warehouse locations, monitor your inventory levels, track product movement, and set automated alerts for low stock, Breadstack is designed for you.

Book a free demo today.