The key to efficient inventory management is a well-balanced combination of demand forecasting, business intelligence, and in-depth customer analytics. However, even the most organized businesses go through the problems of over ordering stock that leads to inventory that cannot be sold, also known as “dead stock”.

Dead stock not only takes up valuable warehouse space but also seriously harms a company’s cash flow and sales. In severe circumstances, it may jeopardize the company’s long-term viability. This article will discuss ways to reduce the possibility of collecting dead stock as well as providing useful advice for managing and reusing excess inventory.

What is Dead Stock?

“Dead stock” is the term used in the e-commerce industry to describe merchandise that is no longer able to be sold and is usually taking up space in warehouses. These products may become unsaleable for a number of reasons, such that they are out of season, old, expired, or of poor quality. Keep in mind that dead stock is not in the same category as returned products because these items have never been purchased by customers.

How Does Dead Stock Impact a Business?

For any business, dead stock may be a major financial burden. Not only does it hold back available cash flow, but it also immediately affects sales and raises the expenses of inventory holding. It also takes up valuable real estate that may be better used in warehouses or on retail shelves.

Financial Loss: Companies spend money to buy inventory with the hope of making a profit, therefore having dead stock becomes a financial loss. This investment becomes pointless because these products are a loss in sales.

Warehouse Costs: Storing inventory requires warehouse spacing. These costs are frequently correlated with labor costs, insurance, and amount of storage space.

Higher Labor Costs: Labor costs associated with high inventory means more management, such as inventory inspections, rearrangement, and more. In the end, labor costs associated with getting rid of dead stock increase costs without bringing in any money.

Opportunity Costs: When dead stock is finally sold, it’s usually sold with major discounts resulting in a loss. This affects the company’s ability to break even or turn a profit because the resources could have been used to manage successful products instead.

Space Restrictions: Warehouses have limited space, therefore dead stock takes up valuable shelf space making it difficult to store more profitable items.

How To Calculate Costs For Dead Stock

Finding the money lost from inventory that you are unable to sell is the main concept behind dead stock calculations. Here are several methods for calculating dead stock.

Calculating Dead Stock Value

You can first calculate the value of dead stock using the same formula you would use to calculate the value of sellable inventory.

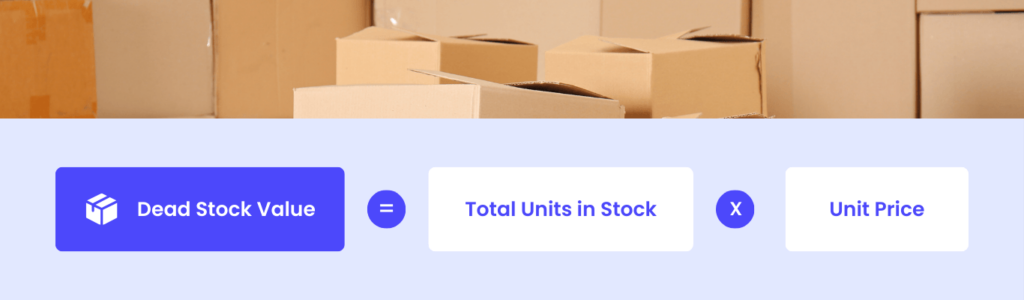

Dead Stock Value = Total Units in Stock x Unit Price

Example: If you had 100 units of dead stock, for instance, and each unit would have sold for $20, you would compute the value as follows:

Value of dead stock: 100 units x $20 each = $2000

Calculating Sunk Costs For Dead Stock

Knowing the initial cost of acquisition is an important part of dead stock. Since there is no revenue from dead stock, this expense is regarded as a sunk cost since it reflects money spent cannot be recovered through sales.

Every company has different costs associated with purchasing inventory, determining the sunk cost of dead stock differs from company to company.

You must total all of the direct costs from the production of the dead stock in order to calculate the sunk cost for your inventory. Usually, these costs consist of:

- Costs of raw materials and labor

- Any overhead connected to the unsold inventory

- The product’s transportation expenses

What Causes Dead Stock And How To Prevent It

Dead stock is often related to ineffective management techniques. However, sales can also be affected by unpredictable market trends that can have a big impact on consumer buying habits. Here are several reasons how businesses end up with dead stock and how to prevent it:

Demand Forecasting

Miscalculations in forecasting can be caused by a variety of problems, including inaccurate data, too optimistic estimates, or uncontrollable external events. Because of this, companies frequently order too much inventory after overestimating customer demand. In the retail industry, these kinds of situations are not unusual and can happen on occasion.

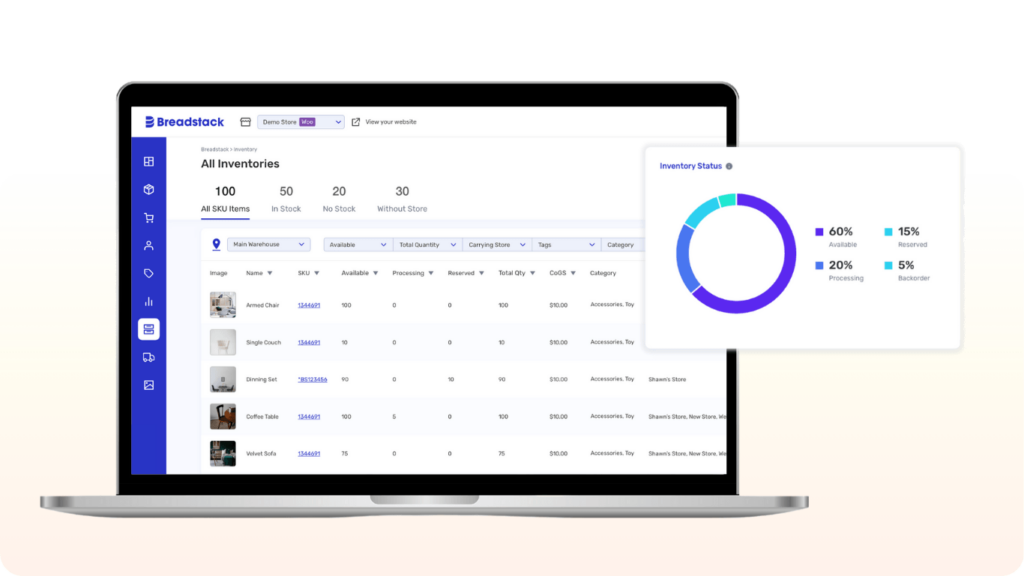

The ability to predict future sales through demand forecasting is essential for making informed decisions about inventory purchases, scheduling promotions, and pricing tactics. Deep insights into future demand trends can be obtained by Breadstack analytics and reporting capabilities such as:

- The rate at which different products are being sold

- Identifying inventory that isn’t moving as quickly

- Estimated number of days left before inventory sells out

- Daily reports on orders and inventory performance

- Additional detailed insights related to inventory, sales, and more

Inconsistent Inventory Purchasing

Businesses may end up with excess inventory as a result of purchasing too many products at once or purchasing items when demand isn’t high.

Making consistent and correct purchase decisions is easier when routinely monitoring a variety of inventory management Key Performance Indicators (KPIs), such as:

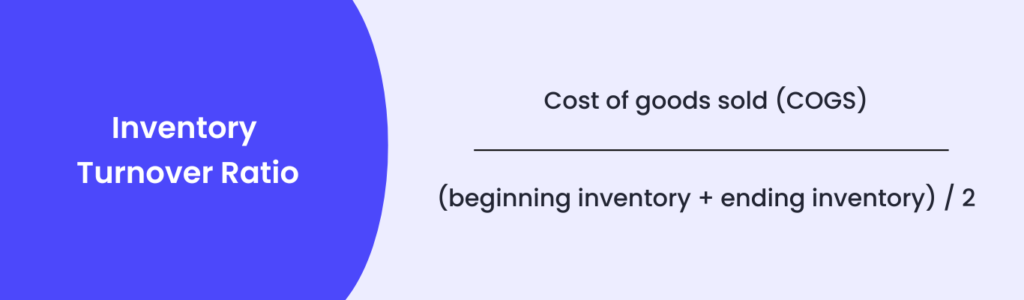

Inventory Turnover Ratio: This KPI measures how quickly stock is sold by keeping track of how often inventory is sold and replaced over a certain time frame.

Reorder point formula: A product’s minimum inventory level before a purchase is required is known as its reorder point. It is determined by multiplying the item’s average daily consumption rate by the order lead time, then adding any required safety stock.

Breadstack’s inventory management system automatically calculates these KPIs through machine learning. It’s able to understand past purchases and customer shopping behavior to provide accurate calculations when to reorder.

Low Sales

There are a number of reasons why a product might not be successful, including price, style, competitors, or inability to meet the needs of the target audience.

Finding the reason behind the low sales is the first step. It might be necessary for you to improve your customer service skills, modify your price, or marketing promotions.

Strategies To Turn Dead Stock Into Opportunities

Businesses periodically deal with the problem of dead stock. It can create losses, but there are ways to lessen the burden effectively and turn them into opportunities. Here are some methods:

Offering Free Gifts With Purchase

Giving dead stock away as a free gift with other purchases is one way to get rid of it. This approach can raise the perceived worth of a customer’s purchase even though its main purpose is to free up storage space rather than increase profit margins.

Research also suggests that receiving a free present increases the likelihood of making repeat purchases, this extra value has the potential to both increase sales and customer loyalty.

Pro tip: If you want to reduce your losses, think about giving away a present exclusively to consumers who spend more than $100.

Creating Product Bundles

Bundling dead stock with a related product and selling the set at a discount is an effective strategy to cut down unwanted inventory and increase average order value. Combining unsold inventory with high-demand items that are likely to sell on their own is a good way to maximize revenue recovery.

Discounts or Sales

The simplest method for handling dead stock is frequently providing discounts and clearance sales. These promotions can generate brand awareness and encourage people to buy.

Source: DSW

Returning Items

Manufacturers frequently have policies allowing returns once a year. In exchange for store credit or a portion of the original cost, they might agree to buy back some of these pieces from you. It may be wise to take advantage of this opportunity and it can be helpful to establish clear policies to oversee this process.

Product Giveaways

Turn your outdated inventory into an engaging social media campaign. Start a giveaway campaign whereby consumers who interact with your business on social media can win dead stock items. To be eligible to win, tell them to like, comment on, or share your content. Using leftover inventory for social media promotions excites your audience and may draw in new followers.

How Inventory Management Software Can Help Get Rid of Dead Stock

By continuously monitoring and modifying inventory levels to match demand, inventory management software is essential in preventing dead stock.

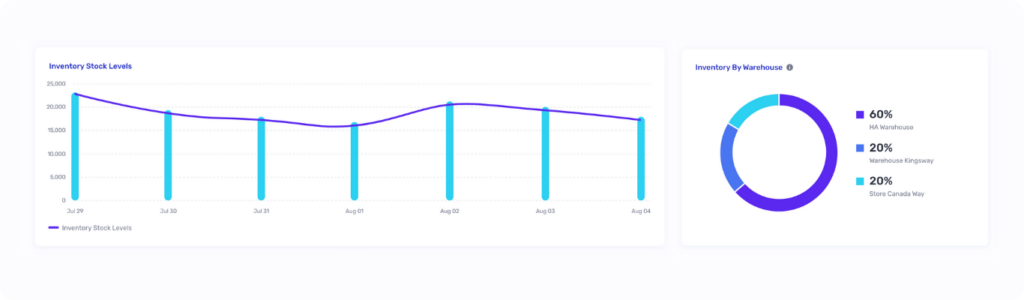

Breadstack uses machine learning algorithms to automatically examine demand trends and sale patterns in order to improve forecasting accuracy. It can also forecast when inventory needs to be restocked automatically. Breadstack helps companies maintain an ideal stock level, lowering the possibility of having extra goods that might go unsold. If you have multiple stores, breadstack allows companies to track inventory across all locations throughout the product life cycle.

In summary, handling dead stock issues is a difficult undertaking for companies of all sizes. Unsold inventory can be the consequence of a variety of factors, including inconsistent ordering procedures, poor demand planning, and quality of products. However, the risk of collecting unsold inventory can be considerably reduced by using inventory management software, being aware of changes in customer demand, and maintaining strict quality control standards.