Inventory is one of the biggest costs for business owners, using inventory management can ensure you’re optimizing and reducing costs where applicable along with so many other benefits.

In this article, we’ll give you all the tips you need to know about inventory management.

Let’s get started.

What is inventory management?

Inventory management is the process of managing inventory from everything from raw materials to finished goods.

The process of inventory management can include ordering, storing, using, and selling inventory.

The goal of inventory management is to minimize costs while keeping consistent stock levels for your product.

Types of inventory to manage

Raw goods – Materials or substances used in early production. Examples: wood, plastic, metal

Work in progress – Partially finished products. Examples: Labour, machines or other equipment used

Finished goods – Available products in stock for customers.

Operation goods – Any materials or supplies used in production but are not part of the final product. Examples: tech equipment, office supplies, and clearing supplies.

10 Tips for inventory management

Having an efficient inventory management system can make a big difference in the operations of a business.

Check out these tips for how to manage your inventory and save money in the process:

#1 Manage your warehouse employees

It’s important to hire employees who are careful with your products. A warehouse employee might be careless with your goods because they are not their own.

By hiring the right employees, you can keep your products safe and avoid mishaps that could damage inventory. An effective inventory management solution starts with a good team.

Check out “What is team management” for more tips on managing employees.

#2 Rotate stock and use skids

All inventory items should be rotated to ensure they do not expire or become unusable.

This includes food, beverage, and hygiene products as well as office supplies. You can use a computerized inventory management system to mark which items have been rotated and what you need to do to rotate them.

If you are using a manual system, you can write this information down on a whiteboard or in a spreadsheet.

You should also make sure to mark which products need to be replaced or need to be moved to the front of the warehouse to be easier to access. Ensure you track inventory properly to avoid any lost inventory items.

#3 Leverage data for better decision making

By tracking which products sell well and which ones don’t, you’ll start to notice some trends.

You can use this information to make more informed decisions and have inventory optimization about the products you order and the amount you reorder.

If a certain product isn’t selling well, you may want to consider removing it from your inventory altogether.

If a product is flying off the shelves, you may want to reorder that product more frequently.

This will allow you to save money because you won’t be ordering too much of a product that isn’t selling.

It will also help you avoid running out of a product and hurting your business in the process.

#4 Be smart about purchasing

Even if you use a computerized inventory management system, you will want to make sure you are being smart about the products you order.

If you overbuy on products that don’t sell, you are wasting money.

Don’t want to underbuy on products either, as this can hurt your business because you run the risk of running out of stock and losing sales as a result.

The data from your inventory levels to determine what you should order next. Also use the data from your multiple sales channels to determine which products are selling better than others.

This will help you better plan your purchases so that you don’t overbuy on certain products and underbuy on others.

#5 Automate as much as you can

Inventory management systems involve a lot of manual processes, so it’s important to try to automate as much of your workflow as possible with inventory management software.

In particular, you’ll want to look into software solutions for tracking your inventory levels. This will allow you to see at a glance how much of each item you have in stock.

Try to automate as many of your processes as you can, so you can focus your attention on other areas of your business.

#6 Track and review your inventory costs

As you track your inventory costs, you’ll want to keep an eye out for anything unusual.

If you notice a pattern where certain items are consistently out of stock, or constantly sell out, it might be time to scale back on purchasing that item.

If certain items are taking up too much room in your facility, it might be time to re-evaluate their importance.

You might be keeping too much inventory or storing it in a manner that’s not cost-effective.

#7 Manage your vendors and suppliers

A lot of the inventory management tips above focus on managing your own inventory and dealing other variables like economic order quantity.

However, you should also try to manage your vendors and suppliers. If you’ve found a reliable supplier, you may want to create a relationship with them. This may allow you to negotiate better prices, or receive discounts for large purchases.

If you notice a supplier is consistently providing low-quality products, or you’re paying more than you should be, you’ll want to switch up your source.

You should also keep tabs on your suppliers, to make sure they are meeting your needs. If they start making changes, you may want to find a new supplier quickly.

#8 Implement demand forecasting

Implementing demand forecasting with your inventory management software will help you plan for the future.

By analyzing past sales data, market trends, and customer behaviour, the software can accurately predict future demand for your products. It allows you to maintain optimal stock levels, preventing overstocking or stockouts.

Anticipating demands means you can be proactive in meeting customer needs and stay one step ahead of your competitors.

#9 Embrace the 80-20 principle

The 80-20 principle is a fundamental concept in inventory management. It states that roughly 80% of your sales come from 20% of your products.

Following this rule it enables you to focus your efforts on managing high-value items while optimizing inventory levels for low-volume products.

By prioritizing your efforts, you can achieve greater efficiency and profitability.

#10 Set reorder points and safety stock

If your software allows it you need to be able set reorder points and safety stock levels for each product.

Reorder points indicate when it’s time to reorder a product to avoid stockouts, while safety stock acts as a buffer to protect against unexpected fluctuations in demand or supply chain disruptions.

By configuring these parameters, you ensure a smooth flow of goods and minimize the risk of inventory shortages.

How inventory management helps in reducing cost

Here’s how inventory management can help reduce costs within your business.

Prevent overstock or overselling

Overstock happens when you purchase more items than you sell. Overselling occurs when you have more items in stock than you actually do.

Both of these are due to inefficient inventory management and can be costly.

Too much inventory or deadstock can cut into your inventory costs, especially if your items expire.

Businesses need to purchase the right amount of inventory so they are not spending extra money on overstock. The extra inventory bought also needs to be shipped and stored which adds to the extra costs.

On the other side, too little inventory leads to a negative customer experience.

Customers aren’t able to get the items they purchased and businesses have to spend time issuing refunds, canceling orders and dealing with bad review

Oversee multiple inventory locations

Business owners with multiple stores have the issue of overseeing all products across the stores or even multiple warehouses. The same can be said for ecommerce businesses with multiple sites.

Not having this information can be costly. Owners need clear and concise inventory management in order to maintain a smooth flow across all stores.

Having all of this information gives you access to trends and predictions for your stores.

If one store is selling more of one item than another, you can make adjustments to move items over to meet the demands of customers.

Utilize demand planning

Inventory management can help gain insight into future demand levels; just like overseeing multiple inventory levels across stores.

Demand planning can take that a step further and predict the need for certain items in the future.

Demand planning if done correctly can lower the inventory carrying costs and better stock levels leading to an increase in your bottom line.

It also takes the guesswork out for business owners preceding trends. Demand planning with Inventory management gives you insight into what’s selling or not

Increase visibility in all areas

Companies need visibility with inventory management. Every point we’ve introduced above around reducing costs has some element of visibility.

Knowing where your inventory is and how it’s performing allows companies to keep tabs on products. You’ll be able to better optimize efficiencies and in turn lower inventory costs.

Without visibility across all inventory areas, you can’t make the adjustments needed to reduce costs. The right inventory management system can ensure you have all the visibility necessary to make better decisions.

Use an inventory management software

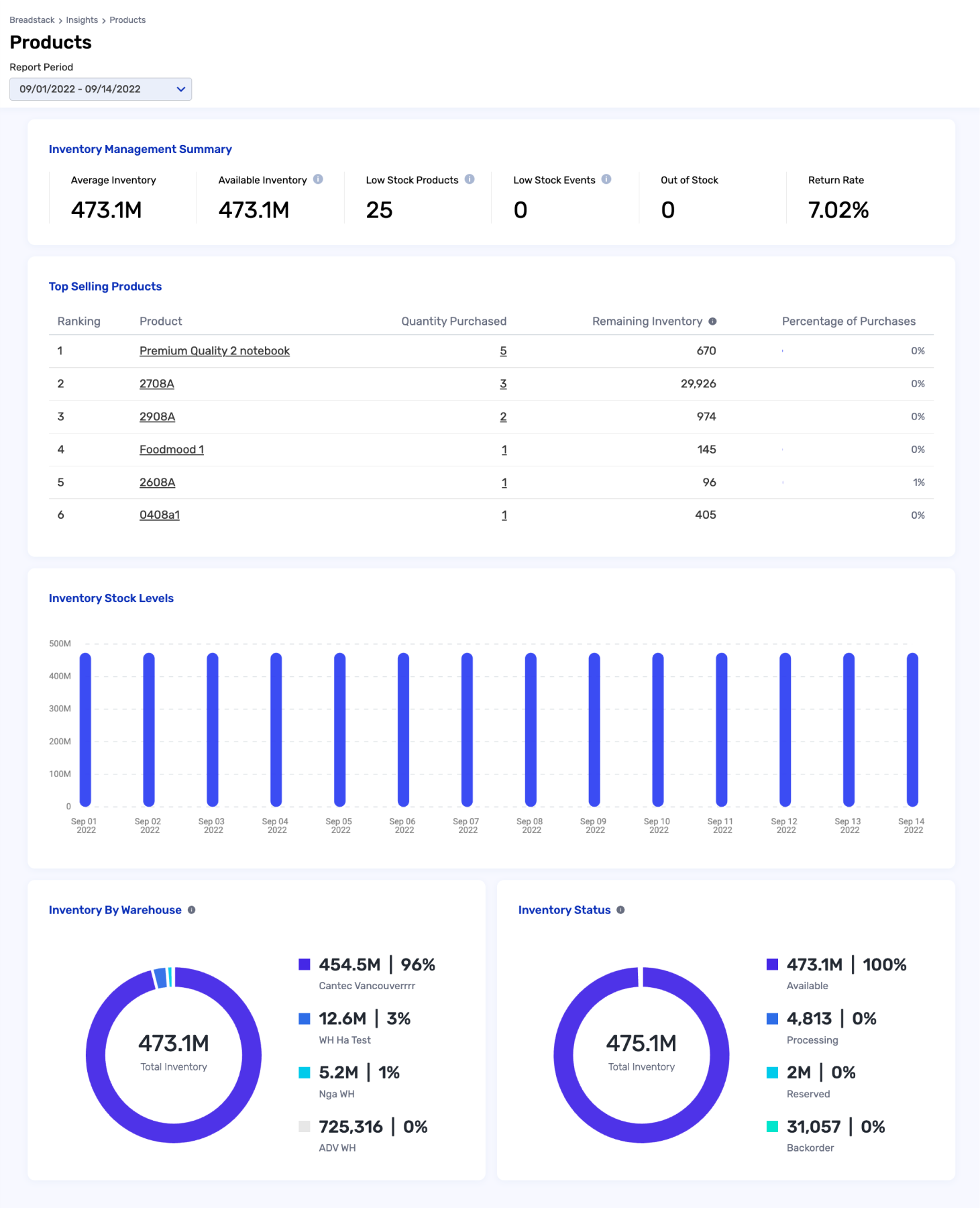

Breadstack offers a commerce hub to give you all the information you need to manage your online store all in one place.

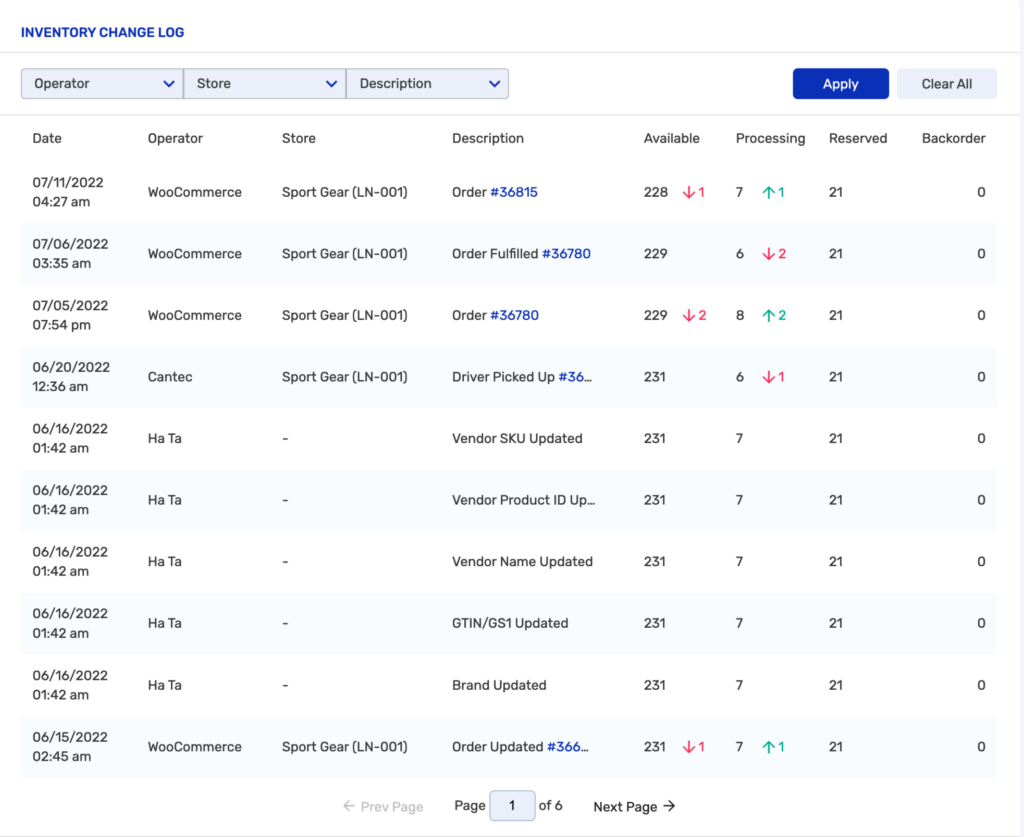

The commerce hub offers an inventory management system. All your products, inventory and order are in one place, so you can have all the up-to-date information you need.

The inventory management system also includes:

multi-location management,

product demand and turnover reporting

order and fulfillment management on one screen

Try our demo today to experience the benefits of Breadstack. Utilize the inventory management system as well as the full experience of the Commerce Hub.